Earring wires are just one of the many ways you can go about adding a creative handmade touch to your design. Depending upon the beads being used, your earring wire can help accentuate the style of your piece. With only some wire and a few other tools, you can create your own earring wire design. Here is a look at some great creative earring wire designs to make today.

1. Copper Hoop Earwires

Using a different metal type with your ear wires can offer new design options for your pieces. In this pair, pure copper is shaped into a small hoop wire and lightly oxidized and filed at the ends for a smooth comfort finish.

2. Oval Ear Hooks

These oval ear hooks are made with 20 gauge wire and hammered on one side flat. These wires were also tumble polished for added strength and shine. For a similar ear hook design, these wires measure at 19-20mm (¾ inch) long and 13 mm wide.

3. Elegant Ear Wires

For these elegant ear wires, use 20 gauge wire with a 1 ⅛ inch drop. Hammered on one side flat and tumbled for strength, these ear wires are a popular option with wide hoop top and elongated tip.

4. French Earring Wires

These basic french earring wires are hand forged from sterling silver wire and hammered on the side and at the tip. With a nice rustic appeal, these wires are crafted with 20 gauge wire and measured at 1 ¼ inch in length.

5. Long Brass Ear Hooks

For some added style and extra long length, do not shy away from these long brass ear hooks. Very lightweight and stylish, these are a chosen design for small charms and dangle beads. These wires are measured at 45mm in length and made with 20 gauge wire. Lightly hammer on one side and at the tip for added style and strength.

6. Swirl French Hook Ear Wires

Here is a look at the a modification to the basic french ear hook design. With an extra curve added at the base, these wires are hammered at the tip and side for strength and beauty. These are a perfect option for drop earring types.

7. Large Leaf Earring Hook

For a more creative design, these large leaf earring hooks are a perfect choice. Made with 20 to 22 gauge wire, they are measured at 1 ¼ inch length and ⅝ inch width. These are a good choice for long elegant style earrings or short drop dangle types.

8. Gunmetal Almond Earwires

These gunmetal ear wires are a great choice for the oxidized silver effect. Formed in a wide tip design, they are lightly hammered to harden and measure at 25mm or 1 inch in length. These almond earwires have the right balance of strength and beauty.

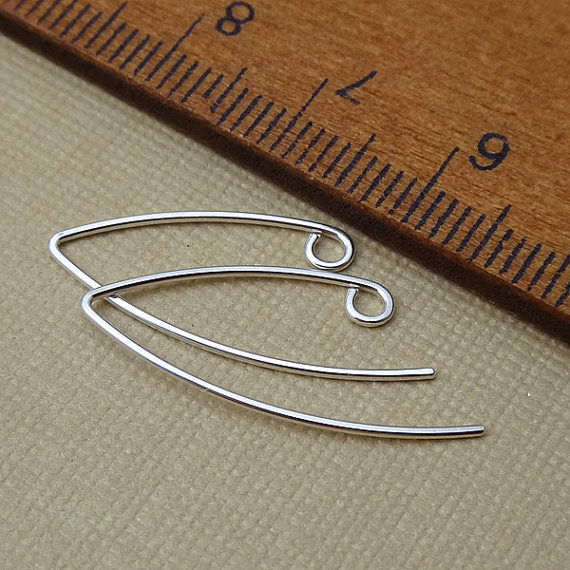

9. Pointed Eye Ear Hooks

These perfectly designed ear hooks are great for long pieces. Made with 20 gauge wire, oxidized, and polished. These are 2 inches in length and offer a great style for drop earrings that include small round gemstones or wide glass oval bead types.

10. Flattened Point Ear Wires

These pointed long ear wires are hammered on one side and rounded at the tip with smooth finish for a comfortable fit. This is a great style of wire gauges that vary from 20-22g. Length is 1 inch with a ⅜ inch width.

YOUR HELP PLEASE……. I NEED TO KNOW WHICH TOOLS TO PURCHASE. I DON’T WANT TO BUY ONE I REALLY WON’T USE MUCH. BUT I DO WANTS TO GET THE ONE NEEDED THE MOST FO BEGINNERS LIKE ME. YOUR REPLY WILL BE GREATFULLY APPRECIATED… CB HOWARD .

Connie,

You can start out with the basic jewelry making plier kits. They should come with five pliers, all of which you will eventually need or use. These include a pair of round nose pliers, flush or side cutter pliers, two flat/long nose, and a bent nose pair. Let me know if you have any other questions on these.

[email protected]

can theses hooped wires go directly in the ear

Belinda, Yes these can go directly in your ear. I would recommend following the tips in my video at the end on filing the tip into a cone shape to ensure you do not have any rough edges. Feel free to use sterling silver wires or other types depending upon the nature of sensitivity of the wearer. Thanks for stopping by and let me know if there are any other questions you may have.

Hi there! I love your gunmetal almond earwires. I was curious what type of oxidizing solution did you use on them? Or could you give a little more information about that process please?

Thanks!

Calsey, Thank you for stopping by and asking your question. The two products you will need for oxidizing is liver of sulfur and a rock tumbler or polishing cloths. If you choose to get a rock tumbler for polishing, do not forget the silver shot. The rest of the items you will need are household products such as a toothbrush for cleaning, dawn dish soap, baking soda and several small mason jars. Since I do not have a blog post or video posted that shows you this process done yet, here is a link to another site that offers some step by step pictures on how to oxidize the ear wires. Hope this helps!

http://www.fusionbeads.com/Using-Liver-of-Sulfur-to-Oxidize-Sterling-Silver

Happy Crafting,

Crystal

Thanks so much for the reply back! Was curious if it was liver of sulfur. Beautiful work! I’ll definitely check out that link you provided.

Thanks for sharing such elegant ear hoops.

I am so happy you found the post enjoyable and useful!

Hi Crystal

Those Gunmetal Almonds are surely eye-catching. Nice work! Curious about the metal used and also.. how did you shape the crisp tip on both the outside and inside of the top bend?

Thanks for your time, RE

Sterling silver is a good choice for oxidizing. It is composed of only 92.5% of silver and the rest contains other metals such as zinc that make it perfect for pulling off a tarnished look when you apply a chemical such as Liver of Sulfur to it. To create the defining tip point at the top of the hook, simply use a pair of needle nose pliers and pinch the desired area you want to point. As you are holding the ear wire in the pliers of one hand, use the other hand (index finger and thumb) to grab each side of the ear wire and pinch inward. Make sure you apply force upward with the pliers as you are pinching inward with the other hand. This will make a defining crease and reinforce the design on top of it. Hammer as desired.

You can check out this article I did on making paddle headpins and use the same techniques to flattern the ear wire.

http://migrate.craftminute.com/how-to-make-paddle-headpins/

Hope this helps!

Crystal

What gauge of wire did you use for the Gun Metal earrings?

Erica,

Thanks for stopping by and asking your question. You can use an 18g wire.

Happy Crafting,

Crystal

Crystal…Can you oxidize all metal? I’m having difficulty with copper plated wire. Thank yo in advance for your expertise & thanks for sharing the fusionbeads website on oxidation, Page

Page,

Thank you so much for your comment and feedback.

When it comes to metals, your alloy metals such as stainless steel and brass do not oxidize. These are man-made for the most part.

Metals such as platinum, gold, and fine sterling silver (99.9% or .999) are naturally resistant. This makes them good for melting with little effect if you choose to make your own ball pins. However, they too will not oxidize.

Other base metals are resistant such as copper, lead, tin, aluminum, nickel, zinc, iron, tungsten and more.

Moving forward, trying to oxidize a coated wire with tarnish resistant metal will present its challenges. Anything gold filled will not oxidize and anything plated or marked as tarnish-resistant.

You will have the best luck with raw copper, bronze, sterling silver (92.5% or .925), and sterling silver-filled products.

Happy Crafting,

Crystal

When making earrings, I like to add backings so I don’t loose my earrings. But all backings seem to be too difficult to push on to the 20 gauge wire without bending/distorting the ear wire. When I use a 18 gauge wire which is thicker, and doesn’t bend so easily, the backings are even more difficult to push on. Any suggestions?

I love your clear, simple videos!

Boni

Boni,

If you are using a 20g wire, you will want an earring stopper that has a whole size of .8mm or above. I was able to locate these earring stoppers that fit wire a wire thickness of .85mm. I have never used this site or their products so I can not speak of their quality. This is just simply to provide you with an example of what you want to look for. Hope this helps!

Happy Crafting,

Crystal

Hi, Crystal, I love all of these earwires. I’m curious how did you get the nice point (crease?) at the top of the ear wire for the Large Leaf ear hook and the almond gunmetal earwires? I read your respond above, do you make the crease before or after you shape the wire? Do you have any photos or a video on this technique? Many thanks!

Cindy,

This technique you can apply to all your questions and use it to create even a greater array of designs. To make a nice indentation or crease with the wire, you want to grip the wire tightly with a round nose pliers. With the other hand or by using a flat nose pliers simply press the wire inward at the point of indentation towards the round nose. This creates a nice notch effect and also helps to harden the wire in your design. Hope this helps!

Happy Crafting,

Crystal

Thank you for the share…..I’m new to jewlery making buy not crafting. I just made number one and I am thrilled…..💜💜💜thank you again grateful newbie.💜💜💜💜

Hi,love the video,could you please do a video on how to make the Almond Ear wire and the Large leave Earring. I always fail when I try to make them. Thanks